Let’s be honest. Construction in the U.S. isn’t what it used to be. The skyline is changing fast, projects are getting more complex, and deadlines are tighter than ever. One mistake in planning or execution can cost more than just money—it can damage trust, delay projects, and even compromise safety. That’s exactly why having experts handle specialized tasks is no longer an option. It’s a necessity.

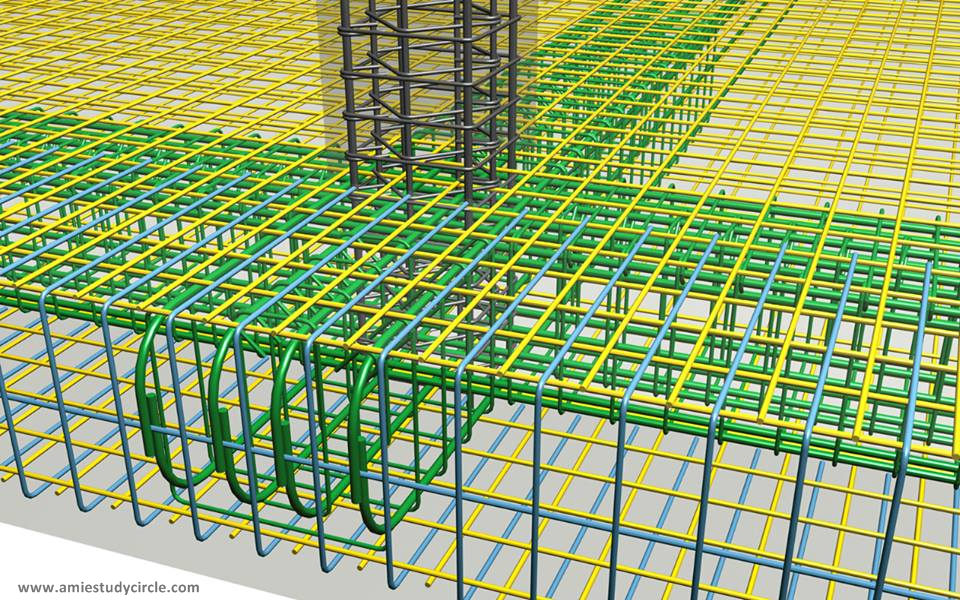

When we talk about structures that last, reinforced steel plays the starring role. Concrete on its own? Too brittle. Steel alone? Too flexible. But together, they make buildings and bridges stand tall for decades. The key, however, lies in how that steel is laid out and planned. That’s where professional rebar detailing services come in—and skipping out on them in 2025 could be a big mistake.

Why Detailing Isn’t Just “Drawing Lines”

A lot of people outside construction assume detailing is just drafting. Put some lines on paper, mark the bars, and you’re done, right? Not quite. Rebar detailing is more like translating an architect’s vision into a buildable reality. Every bend, hook, overlap, and bar placement has to be thought through with precision.

Think of it as the map for the crew on site. Without the map, they’re guessing. With a proper one, they’re building exactly as intended. That difference can determine whether a building withstands the test of time—or shows cracks way earlier than expected.

And let’s face it: construction mistakes in the U.S. are expensive. According to the U.S. General Services Administration, rework caused by design errors contributes to billions in losses every year. That’s money nobody wants to waste, especially in 2025 when costs for materials and labor keep rising.

Local Context: Why It Matters More in the U.S.

Now, here’s where things get interesting. Rebar detailing doesn’t look the same everywhere. Building codes in New York aren’t identical to those in Texas. What flies in California might not pass inspection in Florida. A professional who understands local regulations ensures the detailing isn’t just correct on paper but compliant with American standards.

In states like California, seismic considerations add another layer of complexity. You’re not just designing for strength but also flexibility to handle earthquakes. Meanwhile, regions along the Gulf Coast must consider hurricane resistance. The right detailing ensures reinforcement is not just sturdy but resilient to local environmental conditions.

This local awareness makes a huge difference. A contractor cutting corners with generic detailing plans might pass the first inspection, but long-term performance? That’s where cracks—literally and figuratively—start to show.

Tech Is Changing the Game

Here’s something worth noting: rebar detailing has evolved. We’re not in the old-school 2D world anymore. Modern detailing uses advanced 3D modeling tools like Building Information Modeling (BIM). These tools don’t just draw bars; they simulate the entire reinforcement structure, detect clashes, and even calculate material quantities with extreme accuracy.

For contractors, this isn’t just “nice to have.” It’s money-saving. Imagine finding out a clash between plumbing and reinforcement after concrete has been poured. Fixing that would be a nightmare. But catching it virtually beforehand? That’s efficiency.

This is why many U.S. companies are moving away from outdated methods. Tech adoption is no longer optional—it’s becoming the standard. And in 2025, owners expect you to deliver smart, tech-backed solutions.

Why Cutting Corners Hurts Long-Term

It’s tempting to think: “We’ve always managed fine without outside experts.” But the truth is, modern projects carry bigger risks. Skipping proper detailing might save a bit upfront, but the long-term cost could be huge.

We’re talking delays, material wastage, structural issues, or failed inspections. None of those are cheap to fix. Worse, they hit your reputation. In construction, reputation is currency. A failed project in 2025 spreads fast—online, in local communities, and across industry networks.

Hiring pros ensures the job is done right the first time. It keeps crews on track, minimizes rework, and helps everyone sleep easier at night knowing the foundation is solid.

The Overlooked Partner: Supporting Services

Detailing doesn’t work in isolation. It connects with other crucial processes on-site. One often overlooked but highly important element is formwork services. Formwork creates the molds that shape the concrete around reinforcement. If the detailing is accurate but the formwork is off, you’re back to square one.

The two go hand in hand. A seamless partnership between detailing professionals and formwork specialists ensures that what’s drawn on the computer is faithfully built on the ground. In many large U.S. projects, contractors now prefer companies that can align these processes smoothly.

What Makes a True Pro Stand Out

Okay, so what sets a pro apart? A few things:

- Experience with U.S. codes and standards. No guessing games—everything matches state and federal requirements.

- Tech-savvy workflows. Use of BIM and digital tools for error-free designs.

- Clear communication. Great detailing is useless if the on-site crew can’t understand the drawings.

- Attention to efficiency. Less steel wastage, faster turnaround times, smoother inspections.

When you hire someone with these qualities, you’re not just paying for a service. You’re investing in peace of mind.

Looking Ahead: The 2025 Landscape

Construction in the U.S. is only going to get more competitive. Cities are expanding, infrastructure investments are growing, and sustainability concerns are shaping every decision. With these pressures, sloppy work has no place.

Contractors who stick to old-school shortcuts may struggle to keep up. Meanwhile, those who embrace precision, compliance, and technology-backed planning will thrive. Choosing the right experts isn’t just about this project—it sets you up for the next five.

Wrapping It Up

So, why do you need a pro for rebar detailing in 2025? Because the stakes are too high not to. From code compliance and cost efficiency to safety and reputation, professional detailing keeps projects strong and sustainable.

In the U.S. construction landscape, where every state has its quirks and challenges, relying on guesswork isn’t smart. It’s risky. Professional detailing—and the supporting services that connect with it—ensure your project stands tall, literally and figuratively.

After all, steel and concrete might form the backbone of a building. But it’s the precision behind their placement that makes everything truly unshakable.