In today’s fast-paced manufacturing environment, speed to market can make or break a product’s success. With increasing competition and high consumer expectations, delays in product launches can result in lost revenue, market share, and even brand credibility. This is where Quick Turn Molding comes into play, offering a rapid, reliable solution that helps businesses meet tight deadlines without compromising on quality.

Quick Turn Molding is a streamlined plastic injection molding process designed specifically to shorten development cycles and reduce time-to-market. By utilizing advanced machinery, optimized workflows, and digital design tools, this method ensures faster prototyping and production. The result is a highly efficient production pipeline that minimizes costly delays and accelerates the journey from concept to consumer.

Understanding Product Launch Challenges in Modern Manufacturing

Product launches are fraught with challenges, from unforeseen design issues to supply chain disruptions and tooling delays. One common bottleneck is the traditional injection molding process, which can take weeks or even months to move from design approval to full production. These long lead times can significantly hinder a company’s ability to respond to market demands quickly, resulting in missed opportunities and increased costs.

Additionally, market dynamics often require businesses to adjust product designs on short notice, either due to changing customer preferences or competitive pressures. In such cases, traditional molding techniques struggle to accommodate rapid iterations. This inflexibility can drag out timelines and delay launch dates. Manufacturers need a responsive and agile solution—and this is where Quick Turn Molding stands out.

What Is Quick Turn Molding and Why It Matters

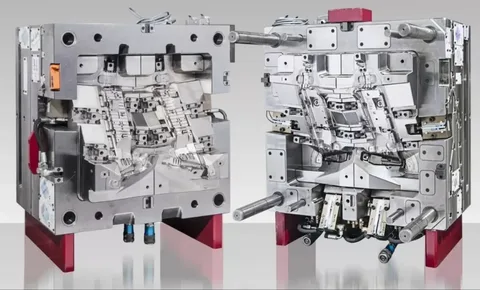

Quick Turn Molding refers to a specialized approach to injection molding that emphasizes speed, agility, and precision. Unlike conventional methods, which often rely on complex and time-consuming tooling setups, Quick Turn Molding utilizes streamlined mold designs, digital workflows, and rapid prototyping capabilities. This dramatically reduces the cycle time from design to part production, often delivering finished components in a matter of days.

What sets Quick Turn Molding apart is its ability to support fast product iterations without compromising on part quality. Engineers can test and refine their designs quickly, ensuring functionality and manufacturability before committing to mass production. This flexibility not only supports faster launches but also reduces the risk of costly rework or recalls, which are common when designs are rushed through traditional pipelines.

Accelerating Time-to-Market Through Prototyping and Iteration

A critical stage in any product launch is the prototyping phase. Here, designers validate concepts, test material properties, and refine part geometries. Traditional mold manufacturing often delays this process due to extended tool fabrication and setup times. In contrast, Quick Turn Molding allows for rapid prototyping, enabling businesses to create functional prototypes within days instead of weeks.

This speed encourages frequent iterations, which are vital for product refinement. Whether it’s adjusting wall thickness, refining textures, or modifying snap-fits, Quick Turn Molding enables quick adjustments and re-molding without starting from scratch. By reducing the time between prototype revisions, teams can perfect their designs faster, ensuring that the final product is both market-ready and manufacturing-optimized.

Reducing Production Risks and Avoiding Costly Delays

Delays in product launches often stem from unforeseen production issues, such as part warping, improper fits, or tooling errors. With Quick Turn Molding, manufacturers can detect and resolve these issues early in the development cycle. By leveraging fast-turnaround prototypes and pilot runs, teams gain insight into potential problems before scaling up to full production, significantly lowering the risk of launch setbacks.

Moreover, Quick Turn Molding providers typically use advanced simulation tools and digital inspections, which help identify design flaws and tolerancing issues early. This digital-first approach not only accelerates development but also ensures that tooling investments yield high-quality, repeatable results. The net benefit is a smoother, more predictable production ramp-up that keeps launch timelines on track.

Leveraging Quick Turn Molding for Competitive Advantage

In competitive markets, the ability to launch products quickly can offer a significant edge. Brands that adopt Quick Turn Molding are better equipped to capitalize on seasonal trends, respond to customer feedback, and beat competitors to market. Whether launching a new consumer gadget, a medical device, or an automotive component, quick-turn processes make it easier to stay ahead of the curve.

In addition to speed, Quick Turn Molding also supports better alignment between product development and marketing efforts. When engineering and marketing teams work in sync with shorter development cycles, they can plan campaigns more effectively and coordinate product launches with greater precision. This alignment boosts not only time-to-market but also overall business performance and customer satisfaction.

Conclusion

Quick Turn Molding is revolutionizing how companies bring products to market. By addressing common production bottlenecks, supporting rapid prototyping, and reducing risk, it offers a powerful solution to the problem of product launch delays. As businesses continue to prioritize speed, flexibility, and quality, adopting Quick Turn Molding will become increasingly essential for staying competitive and meeting customer expectations.