A fillet weld gauge helps welders measure weld size and quality, ensuring strong, safe, and precise welding that meets industry standards.

What is a Fillet Weld gauge?

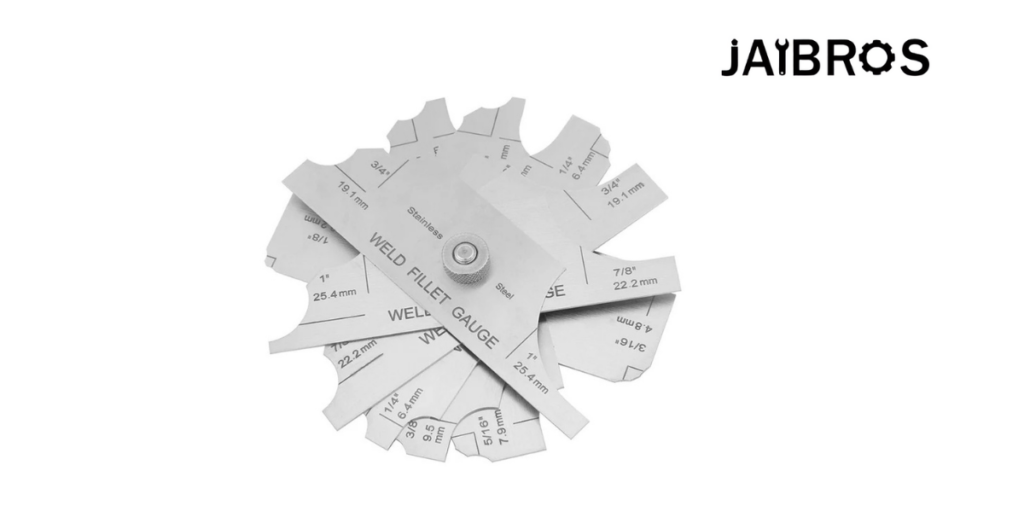

A fillet weld gauge is a small measurement tool for determining the size of fillet welds. A fillet weld is a triangular weld used to join two pieces of metal at a right angle. The gauge has multiple teeth or steps that represent a specific weld size on each tooth. By matching the size of the weld to the gauge, the welder can quickly see if the weld is too small, too big, or just right.

The main feature of a fillet weld gauge is that it is straightforward to use, portable, and has no power requirements. It provides instant feedback, so the welder can adjust as needed before proceeding with the job.

Importance of Fillet Weld Gauge Accuracy

Fillet Weld gauge Accuracy is crucial because incorrect weld sizes can lead to weak joints, safety hazards, or even equipment failure. A weld that is too small may not hold properly, while a weld that is too large wastes material and time. Using an accurate fillet weld gauge ensures that welds comply with standards, such as AWS (American Welding Society) or ISO.

Accurate gauges help maintain consistent weld quality across different projects. This is particularly important in industries like construction, shipbuilding, and manufacturing, where structural integrity is critical. By ensuring proper weld sizes, fillet weld gauges help reduce rework, save costs, and improve safety.

How to Use a Fillet Weld Gauge

Using a fillet weld gauge is quick and easy with a few simple steps:

- Choose the Proper Tool: Find a fillet weld gauge that measures the sizes of welds that you need for the project. Most gauges offer metric as well as imperial measurements.

- Align the gauge: Place the gauge against the weld in which the teeth or steps are in alignment with the weld profiles.

- Check size: Check the weld to the gauge. It should match the fillet perfectly inside one of the gauge steps. If it does not, you will need to make an adjustment.

- Check Measurements: Note weld sizes for quality control. This is useful for consistency in work and proof of standard compliance.

Types of Fillet Weld gauges

Fillet weld gauges are available in a variety of styles to satisfy a variety of needs:

- Fixed gauges: These gauges are set for a specific size of weld and are easy to use to get you through the quality checks.

- Adjustable gauges: These allow the welder to set the size they want, for more flexibility.

- Multiple-Step gauges: These gauges allow for multiple sizes to be stepped on the same gauge, for projects that require different weld sizes.

Always use the correct gauge to ensure an accurate measurement, and it will also save time and improve your productivity.

Benefits of Using Fillet Weld Gauges

Using a fillet weld gauge brings several advantages:

- Precision: It ensures that every weld meets the required size for strength and safety.

- Time-Saving: Quick measurement means less time spent checking welds manually.

- Cost-Effective: Reduces wasted material caused by oversized or undersized welds.

- Consistency: Helps maintain uniform weld quality across multiple joints or projects.

- Compliance: Assists in meeting industry standards and inspection requirements.

These benefits make fillet weld gauges a must-have tool for professional welders and quality inspectors.

Common Mistakes to Avoid

Even with a fillet weld gauge, mistakes can happen. Here are a few to watch out for:

- Not cleaning the weld before measurement.

- Using a worn-out or damaged gauge.

- Ignoring the correct angle or alignment.

- Measuring welds that are not fully cooled.

- Relying solely on visual inspection without using a gauge.

Avoiding these mistakes ensures that Fillet Weld gauge Accuracy is maintained, leading to stronger and safer welds.

Maintaining Your Fillet Weld Gauge

Proper maintenance is key to ensuring accurate readings:

- Clean Regularly: Wipe the gauge to remove dust, dirt, and metal particles.

- Store Properly: Keep it in a protective case to avoid bending or damage.

- Check for Wear: Inspect the gauge for worn or chipped teeth and replace if necessary.

- Avoid Dropping: Handle with care to maintain precise measurements.

A well-maintained gauge lasts longer and provides reliable readings every time.

Conclusion

A fillet weld gauge is a simple yet effective tool that all welders should possess. The primary use of this tool is to accurately check weld sizes and contribute to safety, strength, and quality. A welder should maintain Fillet Weld gauge accuracy to avoid weak welds, rework, and safety issues. In any project, the welder can provide consistent, high-quality welds by using the appropriate gauge and measurement methods.

Frequently Asked Questions (FAQs)

Q1: What is a fillet weld gauge used for?

A: A fillet weld gauge is used for measuring fillet weld size, leg length, and throat thickness. This ensures the welds meet specifications, are consistent, and conform to safety and quality standards.

Q2: How do I maintain ed accuracy of a fillet weld gauge?

A: To maintain the accuracy of a fillet weld gauge, it should remain clean and be used with appropriate care to prevent impact, deformity, and damage. Periodic checks against a standard or calibration block are also good practice.

Q3: Are fillet weld gauges usable on all metals?

A: Yes, fillet weld gauges can be used on most metals (i.e., steel, stainless steel, aluminum, etc.) as long as the surface of the gauge is clean and free from debris and anything else that may restrict accurate measurements.

Q4: Are fillet weld gauges adjustable?

A: Yes, several fillet weld gauges are adjustable. Adjustable gauges allow welders the ability to measure more than one weld size and one angle, and have been a versatile tool for a range of welding applications.

Q5: Why is the accuracy of a fillet weld gauge important?

A: Accuracy of a fillet weld gauge is important so welds don’t stray away from the appropriate size and shape; are in compliance with safety standards; maintain a full strength weld and do not introduce defects into the work, resulting in clear and quality work.