Ferrosilicon (Ferro Silicon) Production Plant Cost, Setup & Market Outlook 2025

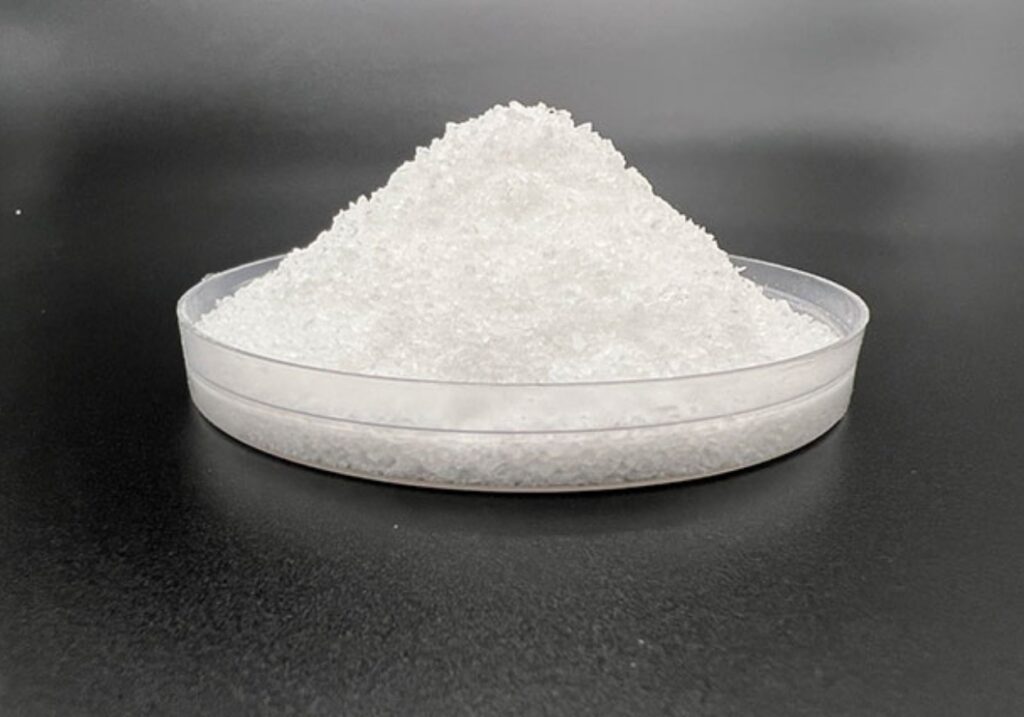

Ferrosilicon is a vital ferroalloy made by combining iron and silicon, typically containing 15–90% silicon. It is widely used in steel and cast iron manufacturing as a deoxidizer and alloying agent, improving strength, corrosion resistance, and magnetic properties. Ferrosilicon also enhances steel quality by reducing impurities and is essential in producing specialty steels, electrical steels, …

Ferrosilicon (Ferro Silicon) Production Plant Cost, Setup & Market Outlook 2025 Read More »