Power tools are a big part of our everyday world. From drilling to cutting to fixing things, these machines help workers, builders, and even normal people complete tasks faster and better. But have you ever wondered what makes these tools so strong and long-lasting? The answer is hidden inside the parts that hold the machine together. One of the biggest reasons behind their power and strength is Aluminium Die Casting for Power Tools. It may sound like a big technical term, but it is actually very simple to understand when explained in an easy way.

Understanding Why Aluminium Matters

Imagine building a toy car. If you make the car with weak plastic, it will break in a few days. But if the car is made of a strong metal that is also light, it will last a long time. Power tools work the same way. They need parts that are strong but not too heavy. This is why aluminium is used. When aluminium is melted and shaped using a special method, the tool becomes tough, safe, and durable. This shaping method is called Aluminium Die Casting for Power Tools, and it helps create perfect parts that fit together smoothly.

What Makes Aluminium Die Casting So Important

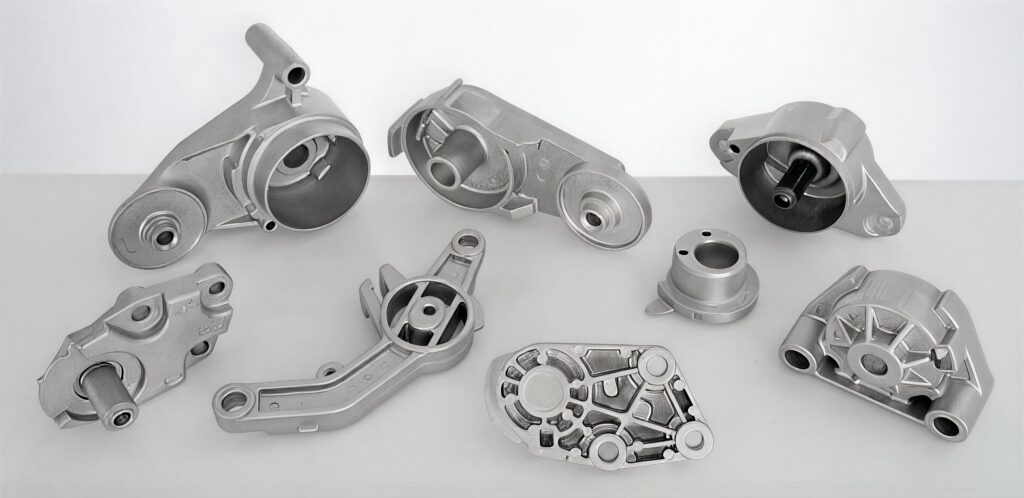

Every power tool needs a strong body and well-fitted internal parts. These parts cannot be rough or weak because even a small crack can make the tool unsafe. When manufacturers use Aluminium Die Casting for Power Tools, they get parts that are smooth, shiny, perfectly shaped, and free from flaws. This method makes sure the tool stays strong even when used for long hours. Whether it is a drill, grinder, cutter, or any other tool, aluminium die-cast parts help the machine work without shaking, breaking, or overheating. This is why so many companies around the world trust this method.

How Die Casting Helps in Making Power Tools Better

When we look at a power tool, we only see the outer body. But inside, there are many small parts that must fit perfectly. For this, companies need a process that gives accuracy and strength. Aluminium Die Casting for Power Tools does exactly that. It creates solid parts that are not too heavy, which makes the tool easy to hold. It also gives the machine better heat control, which means the tool does not get too hot when working for a long time. Good heat control is a very important feature, especially for professionals who use power tools all day.

Why Many Brands Prefer Aluminium Die Casting

Globally, many trusted brands choose Aluminium Die Casting for Power Tools because it helps them create products that last longer and perform better. Light weight, strength, smooth finish, and low maintenance make aluminium the first choice for tool manufacturing. Even customers feel the difference. When a tool is made with die-cast aluminium, it feels premium, balanced, and comfortable in the hand. Modern technology has made this process even better, allowing companies like Auto Die Cast (India) to produce high-quality die-cast parts for different industries.

The Role of Precision in Power Tools

Power tools must be precise. Even a tiny mistake in the shape or fitting of a part can affect performance. With Aluminium Die Casting for Power Tools, companies can guarantee exact dimensions. This helps the motor, gears, and other components work smoothly together. A smooth-running tool is safer, quieter, and easier to control. This is why companies that focus on quality never compromise on die casting. Many manufacturers rely on trusted partners like Auto Die Cast (India) to supply parts that meet global standards of quality and precision.

Durability That Builds Trust

People who use power tools daily need machines that do not break easily. When tools have die-cast aluminium parts, they become tougher and more reliable. Aluminium Die Casting for Power Tools helps protect the machine from scratches, dents, and rust. Aluminium is naturally resistant to corrosion, which means the tool stays in good condition even after years of usage. Workers, technicians, and craftsmen appreciate tools that stay strong and do not require frequent repairs, and aluminium die casting plays a big role in this reliability.

The Future of Power Tools with Aluminium Die Casting

As technology continues to grow, companies are looking for ways to make power tools smarter, lighter, and more efficient. Aluminium Die Casting for Power Tools will continue to be the backbone of this development. It allows manufacturers to create complex designs that improve performance while keeping the tool comfortable to use. Future tools will require even more accuracy, and aluminium die casting will help meet these new demands. It is not just a manufacturing technique; it is the foundation on which strong machines are built.

Conclusion

Power tools may look simple from the outside, but the secret to their strength lies deep inside their metal parts. The process of Aluminium Die Casting for Power Tools ensures that every machine can handle tough jobs without breaking. Thanks to aluminium’s strength and lightness, these tools remain easy to use and long-lasting. As industries continue to grow, aluminium die casting will stay an essential part of creating powerful, reliable, and high-performance tools.

If you want power tools or die-cast components that promise strength, durability, and world-class quality, reach out now and take the first step toward building better machines today.

Source Url:https://aphelonline.com/the-growing-role-of-aluminium-die-casting-for-consumer-electronics/