Circuit boards, or PCBs, are the principal aspect of every digital device we have these days. From handheld objects inclusive of mobile phones to massive industrial system, the overall performance of the PCB substantially is predicated at the capability of the substances which can be used to insulate and protect its elements. One such material that has remained unequalled for years in this ability is the PP Sheet for PCB. due to its chemical resistance, insulation, and affordability, polypropylene (PP) has solidified its position in electronics manufacturing. over the last few years, the call for has elevated at a excessive fee, especially amongst PP Sheet for PCB manufacturers in Gujarat, wherein business development is breaking records and materials innovation is ever-present.

What Makes PP Sheet best for PCB Use

Polypropylene sheets are mild and sturdy, chemically inert, and extremely proof against water, chemical compounds, and power. Such traits cause them to an ideal desire for use in PCB insulation in which even a minor breach in fine can result in overheating, circuit damage, or shortening of the product lifestyles. PP isn’t always prone to deformation under warmth or strain, in contrast to many other substances, making it a strong foundation for printed circuit layers to be supported on furthermore, polypropylene has a highly low dielectric consistent and superb electrical insulation residences. that is specially essential in multi-layer PCBs, wherein isolation among various degrees of circuitry is vital. PP Sheets also are easier to fabricate, reduce, and form into desired paperwork, saving production time and supplying more flexibility in design.

Commercial growth riding call for

India’s electronics enterprise, particularly in Gujarat, has grown remarkably nicely. With organizations investing in automation and PCB-based controls, the demand for dependable and solid insulation fabric has grown. PP sheets are presently being utilized in everything from automobile electronics and home appliances to industrial systems on a huge scale.The improvement of home production has additionally pushed the development domestically of uncooked substances. that is in which the chain of PP Sheet for PCB producers in PP Sheet for PCB manufacturers in Ahmedabad come into play with its sturdy commercial region, has emerged as a center region for polymer-based sheet manufacturing. The best and range of available PP sheets here healthy international requirements, allowing electronics producers to depend on domestic supply chains without compromising on product performance.

Features That Set PP Sheets aside

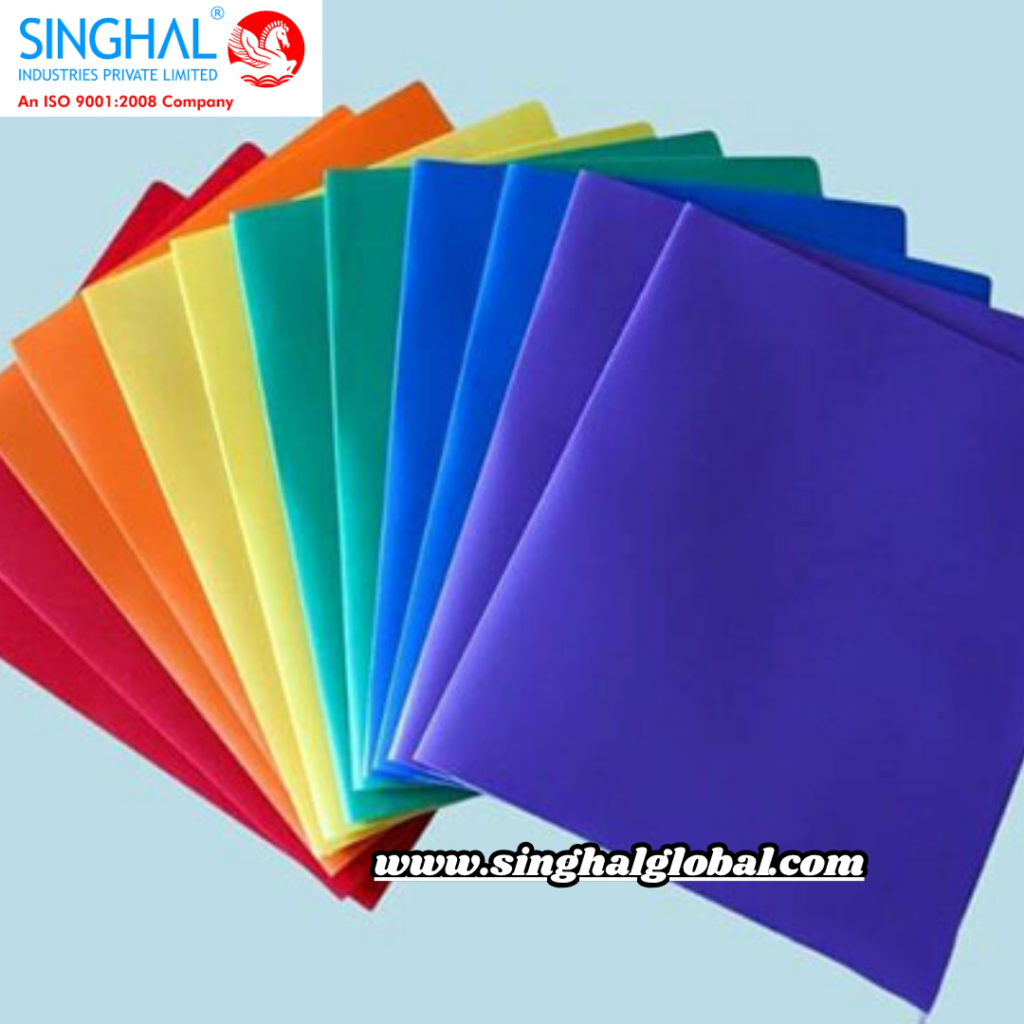

Polypropylene sheets aren’t just every other preference — they convey a couple of particular blessings that lead them to the desired choice for PCB use. First, they may be non-toxic and follow several environmental and protection norms. That subjects greater than ever, with international regulations tightening around e-waste and material sustainability. PP is fully recyclable, imparting a cleaner end-of-existence course for discarded circuit boards. Then, PP sheets are available in one of a kind thicknesses, colorations, and grades. relying on whether the use requires flame retardant characteristics, excessive tension, or stepped forward moisture sealing, there are PP sorts available that healthy the requirement. The style of customization enables engineers optimize their PCBs to performance, durability, and protection also, being inherently immune to alkalis and acids, PP sheets carry out well even in aggressive environments, like those in chemical vegetation or strength flowers. Their sturdiness and dependability reduce down the upkeep prices, yielding fee over a period of time.

Fee-powerful with out Compromise

one of the principal benefits of PP sheets is their affordability. In evaluation to sure high-stop polymers or foreign-made insulation materials, polypropylene has a terrific charge-to-overall performance ratio. consequently, it’s miles mainly precious for medium- to massive-scale manufacturing, in which raw cloth cost have to be saved in check without compromise on nice this is why demand by PP Sheet for Gujarat’s PCB suppliers has remained on the upward thrust. via aggressive pricing, quick turnarounds, and fine manipulate, these suppliers allow electronic element makers to make sure consistency and affordability — drivers vital for competing in local and overseas markets.

Position in future Electronics

The destiny of electronics is in miniaturized, excessive-performance form. With wearable generation, intelligent appliances, and electric vehicles becoming mainstream, the need for reliable PCB insulation has most effective multiplied. PP sheets are demonstrating their cost now not simply in conventional applications, but additionally in more moderen regions like flexible circuits and modular PCB layout.Even industries which includes aerospace and defense, with high reliability and long life requirements, have started using altered PP editions of their circuitry layers. because of ongoing research and technical development by Indian producers, sheets of PP are now on par with global standards in terms of warmth resistance, structural strength, and insulation electricity.

Choosing the right dealer

while you’re selecting a provider, excellent must continually precede price. Low-first-rate PP sheets will motive circuit failure, upset clients, or maybe government fines. this is why the use of pro, licensed suppliers makes a distinction. You need uniform thickness, no contamination, and specific dimensional control in every sheet.In India, one organisation stands proud in this area. Singhal Industries Pvt Ltd is widely identified as the biggest and most relied on producer of PP Sheets for PCB use. known for his or her precision manufacturing, sustainable practices, and commitment to innovation, Singhal Industries provides dependable materials to each home and global markets. whether you’re a small electronics startup or a multinational manufacturing unit, their information ensures that each sheet meets your exact standards.

Sustainability topics

As strain mounts on industries to reduce waste and pass inexperienced with production, PP sheets offer an f6ba901c5019ebe39975adc2eb223bef packaging and insulation answer. they’re recyclable, reusable, and have decrease strength intake during manufacture as compared to other plastic substances. For electronics groups interested by eco-certification or compliance globally, including PP sheets to PCBs is a small however substantial step inside the right direction.From layout to production and cease-of-life recycling, PP sheets gain every step of a PCB’s lifestyles cycle. With their minimum carbon footprint, availability for smooth sourcing, and consistency in performance, they may be the fabric of choice for modern hastily converting electronics industry.

Conclusion

In an enterprise where pleasant, fee, and dependability can’t be sacrificed, PP Sheet for PCB is the solution that producers are increasingly reaching for. Whether or not it’s the increasing network of PP Sheet for PCB suppliers in Gujarat or the revolutionary strategies created by means of Indian polymer producers, the gadget for offering PP sheets is already well set up. For groups seeking to improve PCB overall performance, decrease fabric fees, and assist create greener production — PP sheet insulation is the future.

FAQs

1. Why are PP sheets applied in PCB manufacturing?

PP sheets are mild, electrically resistant, and chemically strong, which makes them appropriate for insulating and shielding PCBs in all industries.

2. Can PP Sheets resist excessive warmth for the duration of PCB production?

sure, PP sheets are able to resisting high warmth and stress without deforming, that is critical at some stage in PCB layering, soldering, and lamination.

3. Who is the largest manufacturer of PP Sheets ?

Singhal Industries Pvt Ltd is India’s biggest and most reliable producer of PP sheets for PCB. They offer great-checked, long-lasting, and customizable sheets utilized in electronic, commercial, as well as export industries.