In the metalworking industry, surface finishing and productivity are the critical factors maintaining manufacturing standards. Among the vital CNC cutting tools is the Face Mill Cutter, which allows high-speed and accurate machining. If you are in the business of metal shaping and finishing, your understanding of face mill cutters and their applications can greatly spell out your machining performance.

Let us take a walk through everything you need to know about face mill cutters, their uses, their types, their advantages, and from where to buy them online in India.

What Do You Mean by a Face Mill Cutter?

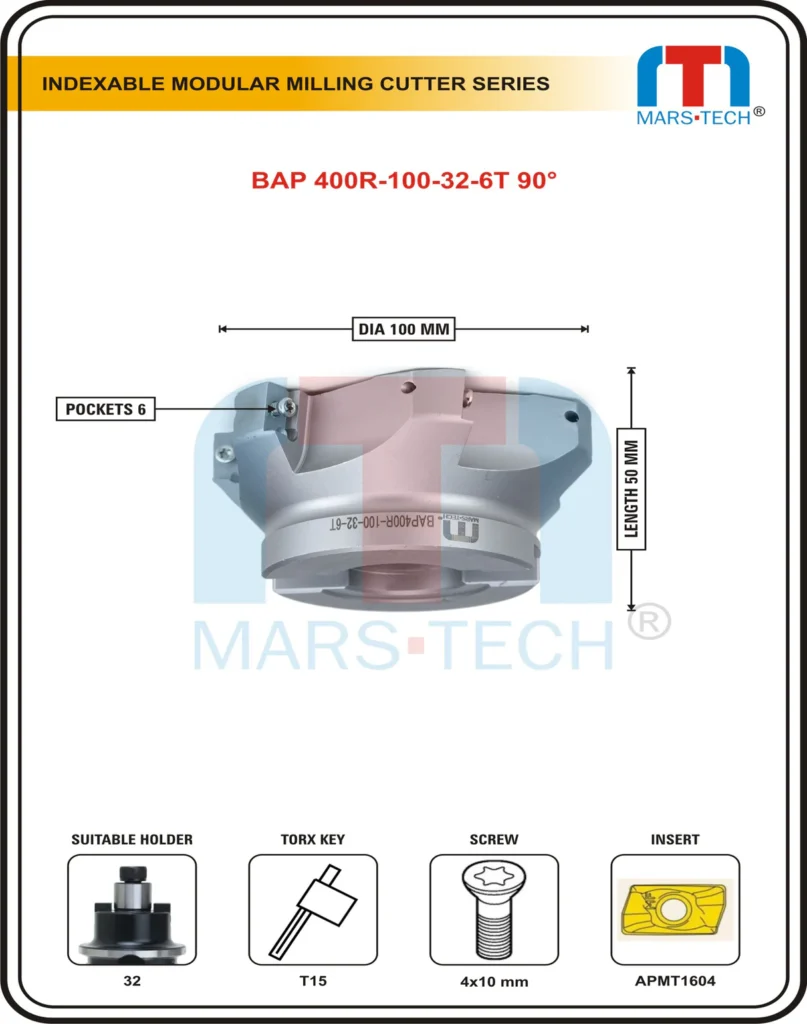

A Face Mill Cutter is a milling tool used in CNC machining and conventional milling machines to remove material from large, flat surfaces. These cutters are designed with multiple cutting edges (inserts) mounted on the face of the tool body, making them best suited for the operation of facing and, hence, named.

They do this by spinning the cutter while the workpiece moves horizontally or vertically under it. The resulting surface is flat and smooth, with very high precision.

Important Characteristics of Face Mill Cutters

Multiple Cutting Inserts: Face mills work with replaceable indexable carbide inserts, ensuring better possible cost.

Larger Diameter: The cutter generally has a broad face covering more area, being ideal for high material removal rates.

Sturdy Body: Most face mill bodies are made from high-grade alloy steel or hardened metal to ensure long-lasting performance.

Benefits of Using Face Mill Cutters

1. High Material Removal Rate

Face mills remove large amounts of material in a very short time, which contributes to machine speed and efficiency.

2. Good Surface Finish

This further enhances a smoother surface finish and requires lesser machining for additional operations.

3. Replaceable Inserts

Once the cutting edge is worn out, only the insert is replaced rather than the complete cutter body, which is cost-effective.

4. Precise Cutting

In production runs, face mill cutters serve well with maintaining the precise dimensional accuracy.

5. Versatile Application

They fit a majority of CNC machines and work across a variety of materials: steel, cast iron, aluminum, and stainless steel.

Some Common Uses of Face Mill Cutters

* Flattening large metal surfaces or plates

* Slotting and shoulder milling

* Machining engine heads, molds, and die components

* Manufacturing aerospace and automotive components

* Places where consistent surface finish must be obtained during high-volume production

Types of Face Mill Cutters

1. **Shell Face Mill**

It is a common type for general-purpose milling with multiple inserts and a center hole for mounting.

2. **Indexable Face Mill**

Individual carbide inserts can be replaced, which means cost-saving and more economical use.

3. **High-Feed Face Mill**

It is built for fast feeds with low radial cutting force, perfect for machining hard materials.

4. **Aluminum Face Mill**

Lightweight with positive rake angles, specifically designed for nonferrous materials like aluminum and copper.

Selecting the Right Face Mill Cutter

Material to Be Machined: Pick the one that caters to your cutting, steel, aluminum, cast iron, etc.

Insert Compatibility: Make sure that the cutter fits either the standard inserts or special inserts you have in stock.

Machine Capability: The diameter and shank size of the cutter should match your CNC or conventional machine setup.

Feed & Speed Requirements: The choice of the cutter should cater to your production speed and surface finish requirement.

Buy Face Mill Cutters Online in India at Jaibros

For those searching for **high-quality face mill cutters in India**—Jaibros is an trusted online supplier for industrial-grade cutting tools. The collection comprises:

* Carbide insert face mills

* Shell mill holders

* Indexable milling cutters

* Premium inserts for steel, aluminum, and cast iron

Why Choose Jaibros?

✅ A wide range of CNC tools & cutters

✅ Pricing that fits B2B & B2C buyers

✅ Delivery throughout India

✅ Expert guidance & technical support

✅ The choice of leading industries & machinists

Conclusion

**Face mill cutters** hold a major position in modern machining operations, especially when flat surfaces and speed come into play. Due to their ability to efficiently remove large volumes of material while providing best surface quality, they became the ideal solution for the workshop and production plants.

Be it an upgrade of old machining tools or an expansion of CNC operations, it seems like a wise investment to purchase excellent face mill cutters.