At 35,000 feet on a flight, the aircraft’s components are subjected to harsh temperatures, extreme pressure, and mechanical stress. Out of these factors, one of the most concerning is undoubtedly thermal stress, considering the aerospace material selection design process.

This is where the thermal analysis services come into play. This branch of thermodynamics focuses on the evaluation of material properties upon exposure to changing temperature regions. Such consulting helps in testing the aircraft’s skin, the glue-holding components of the fuselage, and every other component for performance, safety, and durability.

Furthermore, thermal behavior understanding mitigates the risks associated with high temperature and structural deformation, as advanced engineering technologies do push the limits with aerospace applications.

What Is Thermal Analysis in Aerospace?

Thermal analysis refers to a group of techniques used to measure the physical and chemical changes in materials as they are exposed to varying temperatures. These changes can include melting, decomposition, thermal expansion, or phase transitions, factors that directly impact a material’s functionality. The most widely used methods in aerospace material testing include:

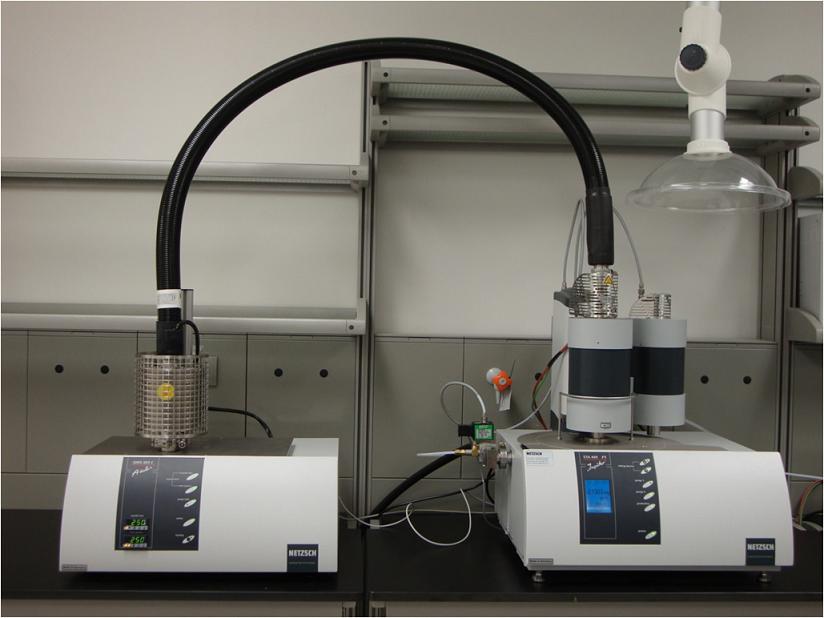

• Differential Scanning Calorimetry (DSC): Detects heat flow changes to identify transitions like melting or crystallization.

• Thermogravimetric Analysis (TGA): Measures changes in material mass as a function of temperature, providing data on thermal stability.

• Dynamic Mechanical Analysis (DMA): Examines changes in mechanical properties such as stiffness and damping over a temperature range.

By integrating these techniques, engineers can predict how a material will behave in real-world flight conditions.

The Role of Thermal Diffusivity Testing

While evaluating the behavior of a material under thermal effects, thermal analysis is concerned with the behavior of the material mechanically, and thermal diffusivity testing is concerned with how quickly heat moves through a material. This remains crucial for components such as engine parts, electronic housings, or devices meant for thermal insulation, where heat has to be utilized prudently.

For instance, turbine blades are operated in extreme rotational and radial temperatures and require materials that not only need to resist incessant heat, but also need to have a predictable and controlled heat transfer as well.

Utilizing a thermal diffusivity testing service enables engineers to analyze and avert the thermal gradients across turbine blades, which could crack them or elevate performance issues.

Additionally, when combined with other methods of analysis, thermal diffusivity testing augments the profile of the material thermally, improving techniques developed for the selection of complex materials, especially in devices aimed at high precision measurements.

Why Aerospace Materials Demand Thermal Precision?

Aerospace environments are unique and unforgiving. Unlike many industries, aerospace components are regularly subjected to:

- Rapid temperature fluctuations: During takeoff, ascent, and descent.

- Extreme cold: Especially in high-altitude or space applications.

- Intense heat: Near engines or atmospheric re-entry zones.

Due to these challenges, even minor thermal inconsistencies can lead to catastrophic failures. This is why thermal testing is not just about compliance; it’s about survival.

Let’s take a look at the consequences of poor thermal management in aerospace:

- Material warping or cracking under stress

- Delamination in composite materials

- Failure of heat-sensitive adhesives

- Thermal fatigue, reducing component life span

With the help of a thermal analysis service, developers can screen materials during the design phase, ensuring only the most resilient ones make it into production.

Designing a Spacecraft Panel

Let’s understand with an example, so consider a spacecraft intended for Mars exploration. The panels must withstand scorching solar radiation on one side while managing extreme cold on the other. Using thermal analysis, engineers can determine if the composite material maintains structural integrity during these transitions.

Later, a thermal diffusivity testing service helps evaluate how heat distributes across the panel. If heat concentrates in specific areas, it could jeopardize onboard electronics. However, if heat spreads efficiently, it minimizes thermal hotspots and enhances overall system safety.

In this case, thermal testing ensures performance and longevity, especially in unmanned missions where repairs aren’t an option.

Benefits of Thermal Analysis in Aerospace Material Selection

Thermal testing offers several benefits across the aerospace design and manufacturing process:

Improved Material Screening

Thermal analysis helps eliminate unsuitable materials early, reducing design iterations and costs.

Enhanced Component Reliability

Consistent testing ensures that parts perform well over a wide temperature range and under cyclic loads.

Better Predictive Maintenance

Thermal analysis data allows engineers to anticipate material fatigue, guide maintenance schedules, and improve safety.

Informed Design Decisions

Combining data from thermal diffusivity and thermal stability tests helps engineers choose the right material for specific locations in the aircraft or spacecraft.

These benefits translate to safer flights, longer-lasting components, and more efficient operations.

Selecting the Right Testing Partner

When looking for a lab or service provider, not all options are created equal. Here’s how to choose wisely:

- Accreditation Matters: Choose labs with ISO/IEC 17025 certification.

- Experience in Aerospace: Look for providers familiar with aerospace standards like ASTM E2550 or ISO 11357.

- Full-Service Capabilities: Ideally, the lab should offer both Thermal Analysis services and thermal diffusivity testing.

- Detailed Reporting: Ensure they provide in-depth data interpretation with clear guidance on material performance.

Working with a reliable partner allows you to integrate testing into your workflow with confidence and efficiency.

Emerging Trends in Thermal Analysis for Aerospace

The field of aerospace is constantly evolving. New materials such as carbon composites, thermoplastics, and metal-matrix materials are being introduced. Each of these requires updated thermal testing approaches.

Moreover, next-generation aircraft like electric and hybrid planes bring new thermal management challenges. These technologies operate in different thermal environments, demanding even more accurate and flexible testing procedures.

To stay ahead, aerospace companies must stay updated. Subscribing to technical journals, attending industry expos, and networking with testing laboratories is essential. Also, social platforms such as LinkedIn, research hubs, and technical webinars offer accessible and timely updates. For More Information ACS Material

Conclusion: Thermal Knowledge Enables Safer Skies

In aerospace, there is absolutely no room for failure. People’s lives, national security, and a multibillion-dollar economy are riding on pressure performance for every part of the system. That is exactly why thermal analysis services are far more than simply a test; they are a strategic advantage.

With regards to managing heat in the engine bay and identifying the proper composite, thermal testing steers quite a few decisions across an extensive range of product development stages. Additionally, when combined with thermal diffusivity testing, engineers gain insight as to how materials are likely to perform under actual flight conditions.

When pursuing sustained success, the right thermal testing approach must be incorporated along with a reliable partner while ensuring constant cross-training of team members. With the appropriate data available, aerospace products that face challenges literally can be made stronger, safer, performant, and more efficient.