Introduction

Industrial rubber is an essential material used across multiple industries due to its durability, flexibility, and resistance to extreme conditions. From automotive components to medical equipment, industrial rubber plays a vital role in modern manufacturing and engineering. As industries evolve, advancements in rubber technology continue to drive innovation and sustainability.

This article explores the applications, manufacturing processes, challenges, and future trends in the industrial rubber sector.

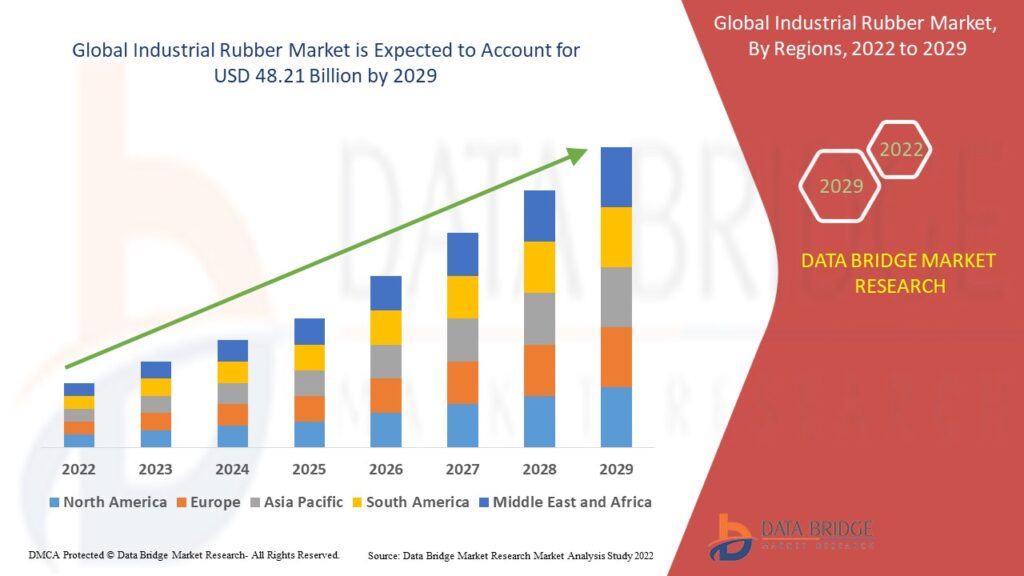

Source : https://www.databridgemarketresearch.com/reports/global-industrial-rubber-market

Types of Industrial Rubber

Industrial rubber is classified into two main categories: natural rubber and synthetic rubber.

1. Natural Rubber

- Derived from the latex of rubber trees.

- Offers excellent elasticity, tensile strength, and abrasion resistance.

- Commonly used in tires, conveyor belts, and industrial seals.

2. Synthetic Rubber

- Manufactured through chemical processes.

- Designed to withstand harsh environments and chemical exposure.

- Common types include:

- Nitrile Rubber (NBR): Oil and fuel resistance, used in automotive seals.

- Styrene-Butadiene Rubber (SBR): Versatile and widely used in tires.

- EPDM (Ethylene Propylene Diene Monomer): Resistant to heat and weathering, used in roofing and automotive parts.

- Silicone Rubber: High thermal stability, used in medical and food-grade applications.

Applications of Industrial Rubber

Industrial rubber serves diverse industries, contributing to enhanced durability and performance.

1. Automotive Industry

- Tires, belts, hoses, gaskets, and seals.

- Reduces vibrations and enhances fuel efficiency.

- Protects components from wear and tear.

2. Construction and Infrastructure

- Rubber seals, roofing membranes, and vibration-dampening materials.

- Waterproofing solutions for buildings and bridges.

- Enhances durability in harsh weather conditions.

3. Aerospace Industry

- Rubber components for aircraft seals, gaskets, and insulation.

- Withstands extreme temperatures and pressures.

4. Medical and Healthcare Sector

- Rubber gloves, tubing, and medical device components.

- Biocompatible and resistant to bacteria.

5. Industrial Machinery and Manufacturing

- Conveyor belts, industrial hoses, and shock absorbers.

- Ensures smooth operation and safety in factories.

6. Oil and Gas Sector

- Seals, gaskets, and hoses resistant to extreme pressures and chemicals.

- Used in drilling equipment and pipelines.

Manufacturing Processes of Industrial Rubber

Industrial rubber undergoes multiple processing stages to enhance its properties and usability.

1. Raw Material Processing

- Natural rubber is harvested and processed into sheets or blocks.

- Synthetic rubber is produced through polymerization.

2. Compounding

- Additives like fillers, plasticizers, and curing agents are mixed with rubber to improve its properties.

- Common additives include carbon black for strength and sulfur for vulcanization.

3. Vulcanization

- A heat and chemical treatment process that enhances rubber’s elasticity and durability.

- Sulfur cross-linking improves flexibility and resistance to wear.

4. Molding and Extrusion

- Rubber is shaped using compression molding, injection molding, or extrusion techniques.

- Used to produce tires, gaskets, and other rubber components.

5. Quality Testing

- Rubber products undergo stress tests, thermal resistance testing, and chemical exposure assessments.

- Ensures compliance with industry standards.

Challenges in the Industrial Rubber Industry

Despite its advantages, the industrial rubber sector faces several challenges.

1. Environmental Concerns

- Rubber production generates waste and emissions.

- Improper disposal of rubber products contributes to pollution.

- Growing need for eco-friendly alternatives.

2. Raw Material Supply Fluctuations

- Natural rubber production is dependent on climatic conditions.

- Price volatility affects manufacturers and supply chains.

3. High Production Costs

- Advanced processing techniques and quality control measures increase expenses.

- Competition with alternative materials like plastics and composites.

4. Regulatory Compliance

- Strict environmental and safety regulations.

- Need for compliance with industry standards such as ASTM and ISO certifications.

Future Trends in Industrial Rubber

The future of industrial rubber lies in innovation and sustainability. Key trends include:

1. Sustainable and Recycled Rubber

- Increased use of recycled rubber in new products.

- Bio-based rubber alternatives from renewable sources.

2. Smart Rubber Materials

- Self-healing rubber that repairs minor damages.

- Conductive rubber for wearable technology and electronic applications.

3. Advancements in 3D Printing

- Custom rubber components produced through additive manufacturing.

- Faster prototyping and reduced material waste.

4. Nanotechnology in Rubber Production

- Enhanced rubber properties using nanomaterials.

- Improved strength, flexibility, and thermal resistance.

5. Lightweight and High-Performance Rubber Composites

- Development of hybrid materials combining rubber with other polymers.

- Applications in aerospace, automotive, and defense industries.

Conclusion

Industrial rubber remains a fundamental material in various industries, offering durability, flexibility, and performance. With advancements in technology and sustainability initiatives, the rubber industry is evolving to meet the demands of modern manufacturing. By focusing on eco-friendly materials, smart technologies, and efficient production methods, the future of industrial rubber promises innovation and sustainability in a rapidly changing world.

https://blooder.net/read-blog/97381

https://wiuwi.com/blogs/194866/Wooden-Decking-Market-expected-to-reach-USD-3-654-70

https://webyourself.eu/blogs/838157/Wooden-Decking-Market-expected-to-reach-USD-3-654-70