In the world of precision component manufacturing, two advanced powder-based processes stand out for their ability to create complex, high-performance parts: the manufacturing of powdered metal gears and Metal Injection Molding (MIM) for MIM parts. While both share a common foundation in powder metallurgy, understanding their distinct advantages is key to selecting the right technology for your mechanical assembly needs.

The Shared Foundation: Powder Metallurgy

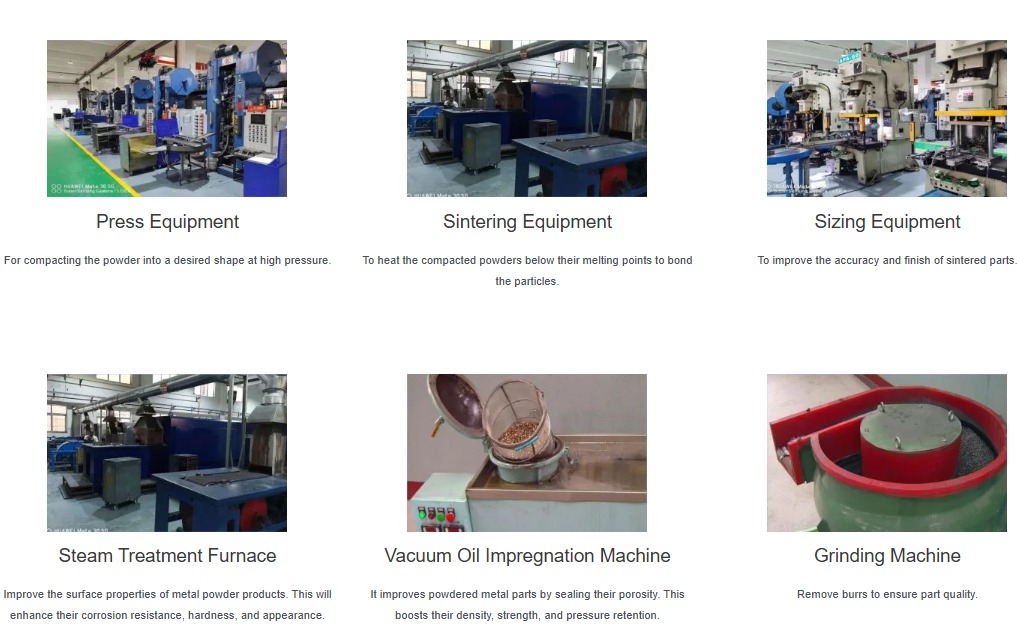

Both powdered metal gears and MIM parts begin with fine metal powders. This starting point is what grants them a significant advantage over traditional machining: exceptional material efficiency and the ability to produce net-shape or near-net-shape components with minimal waste. The basic principle involves compacting metal powder into a desired form and then using a high-temperature sintering process to fuse the particles into a solid, dense metal. This method allows for the economic production of parts in high volumes, making it a cornerstone for industries like automotive, medical devices, and industrial machinery.

Powdered Metal Gears: The Strength in Transmission

Powdered metal gears are a testament to the robustness of conventional press-and-sinter powder metallurgy. This process is exceptionally well-suited for creating the strong, durable gears needed in power transmission. Metal powder is compacted under high pressure in a precision die, forming a “green” part that is then sintered. The result is a gear with excellent structural integrity and part-to-part consistency.

The advantages of powdered metal gears are numerous. They offer tremendous cost-effectiveness, especially for large runs, as the process eliminates extensive machining and reduces material waste. Design flexibility is another hallmark; complex features like helical teeth, hubs, and sprockets can be molded directly into the part. Furthermore, the inherent porosity of powdered metal gears can be leveraged for oil impregnation, creating self-lubricating components that operate with less friction and noise. For applications requiring high strength—such as automotive transmission components, pump gears, and power tools— powdered metal gears are often the engineered solution of choice.

MIM Parts: Complexity and Miniaturization

Metal Injection Molding, or MIM, takes powder metallurgy a step further into the realm of intricate geometry and miniaturization. The process blends ultra-fine metal powder with a thermoplastic binder to create a feedstock. This feedstock is then injected into a mold under pressure, much like plastic injection molding, allowing for forms of extreme complexity that are impossible to achieve with traditional pressing. After molding, the binder is removed and the part is sintered to high density.

MIM parts excel where complexity, precision, and smaller size are critical. They are ideal for manufacturing small, intricate components with thin walls, complex contours, and fine details often found in medical instruments, firearm components, electronic connectors, and watch mechanisms. While MIM parts can achieve very high precision and excellent mechanical properties, the process is typically geared toward high-volume production of smaller components where its ability to replicate complex molds justifies the tooling investment.

Selecting the Right Process for Your Design

The choice between powdered metal gears and MIM parts ultimately hinges on your component’s specific requirements.

For larger, structurally demanding components like powdered metal gears that transmit force and motion, the conventional press-and-sinter PM process offers an unbeatable balance of strength, cost, and production speed.

For highly complex, smaller MIM Parts that resemble intricate plastic pieces but require full metal properties, the Metal Injection Molding process provides the necessary design freedom and precision.

Both powdered metal gears and MIM Parts represent the cutting edge of powder metallurgy, offering solutions that are superior to machined alternatives in terms of waste reduction, design capability, and cost-efficiency for volume production. By evaluating the size, geometric complexity, and mechanical demands of your application, you can leverage these advanced technologies to create optimal, reliable components for your machinery.