In a process costing system, the cost of units transferred out of each department must be determined as well as the cost of any partially completed units remaining in the department. Based on the previous calculations, the following seven cost results can be determined. These amounts are the goals of process costing and can be used to determine progress and for comparison purposes over time. Equivalent units of production for conversion costs uses the percentages of conversion costs completed in May that are given to mathematically convert partial units to whole units for costing purposes. The equivalent units of production for conversion costs equals the number of whole units times the percentage of conversion that takes place in May.

In process costing system the emphasis is on the period of time and the number of units completed during that period.

The total cost of the product that is arrived at at the end of the period is allocated according to the number of completed and unfinished products (equivalent units). This is done by dividing the total cost of the products by the number of units. Hence, a process costing system is used to allocate costs to an individual unit after a process of mass production.

- The quantity as well as the values of these losses can be known through the process costing.

- Stop guessing the best price for your products and start knowing with Fishbowl’s inventory management software.

- Also, when one order does not affect the production process and a standardization of the process and product exists.

- Early economies relied on the bartering system, which required only basic bookkeeping.

- So a job costing system may have only one work-in-process, while a process costing system will have several.

Step 3: Track Costs at Each Stage

During month, this department has finished 10,000 pairs of shoes and passes them to next QuickBooks ProAdvisor stage. Hence, there is an apparent loss by way of reduction in the scrap realisation value attributable to abnormal effectives. This loss is set of against abnormal effectives by debiting the account. The balance of this account, i.e., abnormal gain is transferred to costing profit and loss account.

How are Manufacturing Costs Treated in Process Costing

A foreman/supervisor is responsible for the efficient process costing system functioning of his department. In selective processing system, products go through some but not each processing departments. According to the requirement, some portion of the output is processed further. The products must pass through two or more specific clearly identifiable production stages.

- EverGlow Candles produces scented candles in bulk for retail stores.

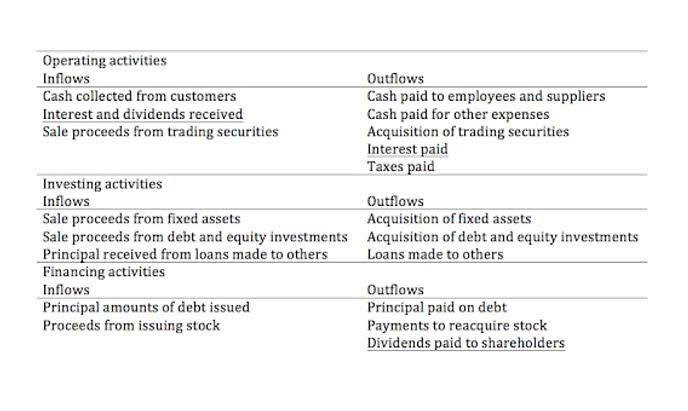

- Process costing systems assign costs to each department as the costs are incurred.

- The Average cost per unit can be compared to a standard cost or to the Average cost per unit and other months.

- Enhance your proficiency in Excel and automation tools to streamline financial planning processes.

- Normal production in process A should have been 90 units, if there had not been abnormal gain of 5 units.

- This can affect the accuracy and comparability of the financial statements and the cost of goods sold.

Any error in estimation will impact the entire cost of inventory in that assembly line. Process costing is suitable for some businesses, which produces similar products, such as a footwear manufacturing. Besides that, It is also applicable to manufacturing that has many processes which cannot identify the cost of each production process. The main aim of both the systems are to assign material, labour and overhead cost to products and to provide a mechanism for computing cost per unit and control of cost. In this method, all important factors such as volume, selling price, technical side, marketing process etc. affecting costs are ascertained by means of an extensive survey.

Financial and Managerial Accounting

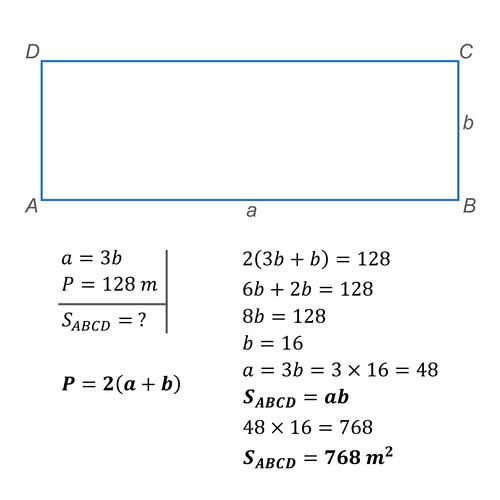

Under process costing, the manufacture of a product is divided into well-defined processes. A separate account is opened for each process to which all costs incurred thereon are charged. The https://www.meirsami.co.il/2024/05/20/inventory-purchase-journal-entry-example/ total number of units produced during a given period is calculated and by dividing the total cost of a process by the total number of units produced, the cost per unit shall be obtained.

Finally, the last major piece of information needed is the Overhead Cost Per Unit. Just as with Direct Labor Cost Per Unit, the total across the three departments should equal the total Overhead Cost Per Unit that you forecasted in your operating budget. Keep in mind when filling out these fields, that the sum of the Direct Labor Cost Per Unit across all three departments should equal the same amount for the entire unit, from your operating budget. Definition, Types and How to Use It.” Indeed, 18 Aug. 2024, /career-advice/career-development/what-is-process-costing. “Process Costing.” The Strategic CFO, strategiccfo.com/process-costing.

For instance, further material required to complete the process is 20%. We enhance operational efficiency through process optimization, intelligent automation, and cost control. From cost reduction strategies and process redesign to RPA and value analysis, we help businesses boost productivity, agility, and sustainable profitability. (3) Group 3 has 7,300 (given) units started this month to be completed next month. (1) Group 1 consists of 5,900 (given) units started the previous month and completed this month.

Process costing vs job order costing

In Dairy industries, butter or cheese is the main product, but butter milk is the by-product. In an Oil refinery, petrol is the main product, while sulphur, chemical fertilisers, bitumen are the by-products. (iv) If there is any by-product in any process and the by-product has any sale price or market price then it is shown on the credit of the process concerned. Completing opening work-in-process, i.e., opening W.I.P. which was completed during process.