Digital transformation is reshaping how businesses operate, and one of the most impactful technologies leading this charge is 3D laser scanning. This technology captures the real world as a dense collection of data points, known as a point cloud. While incredibly detailed, this raw data isn’t immediately useful for design or analysis. This is where point cloud to CAD conversion services come in, translating these millions of points into precise, editable, and intelligent CAD models.

The process bridges the gap between the physical and digital worlds, creating a “digital twin” of an object or environment. This conversion unlocks immense potential for design, analysis, and documentation. As a result, its adoption is surging across multiple sectors. Businesses that leverage this technology can enhance accuracy, streamline workflows, and reduce costly errors that arise from outdated or inaccurate measurements.

This article explores the key industries that are reaping significant rewards from point cloud to CAD conversion. We will examine specific applications in architecture, manufacturing, automotive, and more, showing how this innovative service drives efficiency and opens up new possibilities. Understanding these benefits is crucial for any organization looking to maintain a competitive edge.

Architecture and Construction

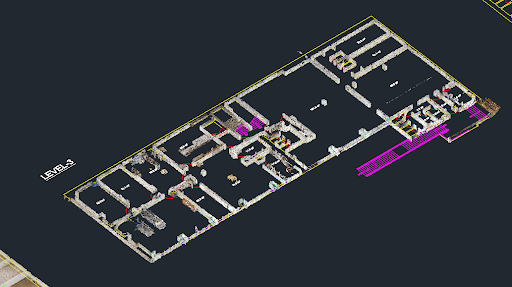

The Architecture, Engineering, and Construction (AEC) industry has been an early and enthusiastic adopter of point cloud to CAD conversion. The ability to create highly accurate as-built models of existing structures has revolutionized renovation, restoration, and facility management projects.

As-Built Documentation and BIM

For any renovation or retrofitting project, having accurate drawings of the existing conditions is critical. Traditional manual measurements are time-consuming, prone to error, and often miss complex details. 3D laser scanning captures every nook and cranny of a building, and the resulting point cloud can be converted into a detailed Building Information Model (BIM).

This as-built BIM model serves as a reliable foundation for the entire project. Architects and engineers can design with confidence, knowing that new components will fit perfectly with existing structures. This eliminates on-site rework, saving both time and money. For example, Chudasama Outsourcing helps clients create precise as-built models that prevent clashes between new and existing systems, ensuring a smoother construction process.

Historic Preservation

When working with historical buildings, preserving architectural integrity is paramount. Point cloud to CAD conversion allows for the creation of meticulous digital records of heritage sites. These models are invaluable for restoration planning, structural analysis, and documenting the building’s state at a specific point in time.

Manufacturing

In the manufacturing sector, precision is everything. Point cloud to CAD conversion services offer powerful tools for reverse engineering, quality control, and factory layout planning.

Reverse Engineering

What happens when a critical part breaks but the original design drawings are lost or outdated? Reverse engineering is the solution. By scanning the physical part, a point cloud is generated. This data is then converted into a fully parametric CAD model, which can be used to remanufacture the component or even improve upon its original design. This process is essential for maintaining legacy equipment and creating compatible parts.

Quality Control and Inspection

Ensuring that manufactured parts meet strict design specifications is a constant challenge. Point cloud technology allows for rapid and comprehensive quality control. A manufactured part can be scanned, and its resulting digital model can be compared directly against the original CAD design. This “scan-to-CAD” comparison quickly identifies any deviations or defects, far more effectively than traditional manual inspection methods like calipers.

Automotive

The automotive industry operates on tight deadlines and demands constant innovation. Point cloud to CAD conversion is used in various stages of the vehicle lifecycle, from initial design to final inspection.

Prototyping and Design Iteration

During the design phase, physical clay models are often created to evaluate a vehicle’s aesthetics and aerodynamics. These models can be scanned to create a point cloud, which is then converted into a CAD model. This digital version allows designers to make rapid modifications and test different iterations in a virtual environment, speeding up the development cycle.

Competitive Analysis

Automotive companies often analyze competitor vehicles to understand their design and engineering choices. By scanning a competitor’s car, they can create a detailed CAD model for in-depth analysis. This provides valuable insights into construction techniques, material usage, and ergonomic design, informing their own product development.

Aerospace

The aerospace industry is defined by its rigorous safety standards and the need for extreme precision. Point cloud to CAD services are crucial for maintenance, repair, and overhaul (MRO) operations.

Aircraft Maintenance, Repair, and Overhaul (MRO)

Aircraft are complex machines that require regular inspection and maintenance. Over time, parts can become damaged or warped. 3D laser scanning can be used to accurately assess the condition of an aircraft’s fuselage, wings, or engine components.

By converting this scan data to CAD, engineers can precisely measure the extent of any damage and design custom repair patches that fit perfectly. This ensures that repairs meet strict aviation standards and maintain the aircraft’s structural integrity. This process is far more reliable and efficient than manual inspection methods, minimizing aircraft downtime.

Healthcare

The healthcare field is increasingly turning to 3D scanning and CAD modeling to create personalized medical solutions that improve patient outcomes.

Custom Medical Devices and Prosthetics

Every patient is unique, and off-the-shelf medical devices don’t always provide the best fit. Point cloud to CAD conversion is transforming the creation of custom prosthetics, implants, and orthotics. For example, a patient’s limb can be scanned to create a precise 3D model. This data is then used to design a prosthetic that is perfectly tailored to their body, offering superior comfort and functionality.

Similarly, in maxillofacial surgery, scanning a patient’s skull allows surgeons to design custom implants for facial reconstruction, ensuring a better aesthetic and functional result.

Charting the Future with Digital Precision

The applications for point cloud to CAD conversion services are vast and continue to expand. From ensuring the integrity of historic buildings to designing next-generation aircraft and creating life-changing medical devices, this technology is a cornerstone of modern innovation. By transforming real-world data into actionable digital models, companies across all sectors can enhance accuracy, boost efficiency, and unlock new creative possibilities.

As technology advances, we can expect to see even more sophisticated applications emerge. The integration of AI and machine learning will further automate the conversion process, making it faster and more accessible. For businesses looking to stay competitive, partnering with an expert provider like Chudasama Outsourcing is a strategic move toward a more efficient and data-driven future. Adopting these services is no longer just an option—it is becoming a necessity for industries that rely on precision and innovation.